What is DMAIC?

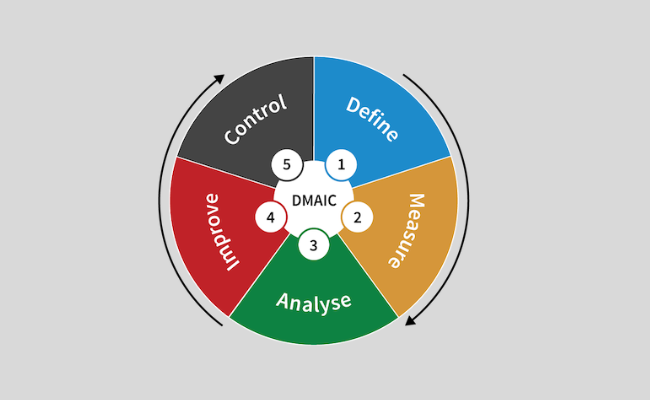

DMAIC is a structured problem-solving method used to improve processes. It stands for Define, Measure, Analyze, Improve, and Control. Originating from Six Sigma, this framework helps organizations solve problems efficiently using data and process-driven decisions.

It is one of the most reliable ways to bring systematic change without relying on trial-and-error methods. By breaking down the improvement process into five clear steps, DMAIC reduces risk, increases clarity, and delivers measurable results.

1. Define: Clarify the Problem and Set Goals

The first phase focuses on identifying the problem. Clear definition ensures everyone understands the objective. Teams begin by stating the project scope, purpose, and expected results. A well-defined problem lays the foundation for meaningful progress. Without it, teams may chase symptoms or misalign their focus.

Key elements include:

- Problem statement: Precisely articulates the issue. Avoids ambiguity.

- Project charter: Outlines the scope, team roles, deadlines, and success metrics.

- Voice of the customer (VoC): Captures expectations and feedback to align improvements with customer needs.

- Timeline and boundaries: Prevents scope creep and maintains focus.

A thorough Define phase minimizes misunderstandings. It forces clarity. Teams must agree on what success looks like before moving forward.

The process often involves stakeholder interviews, process mapping, and a SIPOC diagram (Suppliers, Inputs, Process, Outputs, Customers) to visualize the entire workflow. These tools sharpen focus and ensure alignment.

2. Measure: Collect Data and Establish Baselines

In the Measure phase, data becomes the foundation. Teams identify key performance indicators and gather information on current process performance. This stage is about creating a factual baseline.

Core activities:

- Identify what to measure: Not everything is relevant. Focus on metrics that impact the problem directly.

- Select data collection tools: Checklists, forms, and digital logs ensure consistency.

- Validate measurement systems: Measurement System Analysis (MSA) confirms accuracy.

- Record baseline performance: Establishes a benchmark for improvement.

Accurate data builds credibility. It ensures future changes are evaluated against real numbers, not opinions. Errors in this stage compound later. That’s why measurement systems must be validated for repeatability and reproducibility.

Using tools like Gage R&R studies, teams test measurement consistency. Without validation, flawed metrics may mislead decisions. Teams often visualize data using histograms, control charts, or box plots to understand variability and trends. This phase quantifies the problem and confirms that it’s worth solving.

3. Analyze: Find the Root Cause

Once data is in hand, the next step is analysis. The goal is to understand why the problem exists, not just where it appears. The difference between a symptom and a root cause determines whether a fix is temporary or permanent.

Common tools include:

- Cause-and-effect diagrams (Ishikawa or fishbone): Organize potential causes.

- Pareto analysis: Focuses on the few causes with the biggest impact.

- Regression analysis: Identifies relationships between variables.

- Hypothesis testing: Confirms whether suspected causes are statistically significant.

Teams dig through the data to test theories. Each clue narrows down possibilities. Often, more than one root cause exists. Data segmentation helps identify process variation by time, shift, or location.

Root cause analysis must be driven by data, not intuition. Jumping to conclusions here leads to wasted effort.

By linking cause and effect, teams gain confidence that fixing the issue will yield sustainable improvements. Process maps, failure mode and effects analysis (FMEA), and 5 Whys are also commonly used to deepen understanding.

4. Improve: Develop and Test Solutions

With root causes identified, the Improve phase focuses on change. Ideas are generated, tested, and validated against performance goals. The emphasis is on practical, tested solutions rather than theoretical fixes.

Steps often include:

- Brainstorming sessions: Encourage diverse input and creativity.

- Design of Experiments (DOE): Tests multiple factors efficiently.

- Pilot testing: Small-scale trials reduce risk before full rollout.

- Cost-benefit analysis: Ensures the fix is worth implementing.

Ideas must align with data. The most popular idea isn’t always the most effective. Solutions are tested under controlled conditions to validate their impact. If results improve, the solution moves forward.

Standardization often follows successful pilots. Teams document the change, update training materials, and communicate expectations clearly. This phase may involve new technologies, workflow changes, or redesigned roles.

Improvement doesn’t mean adding complexity. The best solutions often simplify. The goal is a process that delivers better results with fewer errors and delays.

5. Control: Sustain Gains and Monitor Results

The final phase ensures improvements last. Without control, gains fade, and processes slip back. Sustained success requires ongoing vigilance and system support.

Key control methods:

- Standard operating procedures (SOPs): Document best practices.

- Control charts: Monitor process behavior in real time.

- Ongoing training: Reinforces knowledge and accountability.

- Ownership assignment: Ensures someone monitors the new process.

Control means stability. It transforms improvement from a one-time win into a permanent way of working. Any variation should trigger investigation.

Mistake-proofing methods (poka-yoke), visual controls, and regular audits often support the Control phase. Performance dashboards track leading indicators. Teams conduct periodic reviews to ensure the process stays on track.

Without a solid Control phase, even the best improvements erode. Habits return. Performance dips. A strong finish here protects the time and effort invested in the project.

Why DMAIC Matters

DMAIC offers a repeatable path to improvement. It reduces guesswork and replaces it with facts. Instead of jumping to solutions, teams move step by step, validating each action.

Used correctly, DMAIC can:

- Reduce costs

- Eliminate defects

- Improve quality

- Increase customer satisfaction

- Enhance efficiency

Its strength lies in structure. Every phase builds on the last, creating momentum toward lasting change. Unlike ad hoc methods, DMAIC creates documentation, evidence, and clarity at each step.

Organizations that use DMAIC report faster decision-making, lower failure rates, and stronger team alignment. It drives both short-term wins and long-term cultural shifts.

Common Mistakes to Avoid

Misusing DMAIC can waste time and resources. Several pitfalls can weaken results:

- Skipping phases: Each stage has purpose. Omitting one causes blind spots.

- Poor data quality: Flawed data misleads teams. Always validate measurement systems.

- Jumping to solutions: Assumptions short-circuit the process. Confirm causes first.

- Lack of stakeholder engagement: Excluding key voices can lead to resistance.

- No sustainability plan: Without control, even the best solutions decay.

Process discipline is crucial. Rushing through steps undermines the entire project. Teams must resist the urge to fix quickly and instead follow the path fully.

DMAIC vs. PDCA: What’s the Difference?

Both DMAIC and PDCA (Plan-Do-Check-Act) improve processes, but they differ in depth.

- DMAIC suits complex problems. It is data-heavy and structured.

- PDCA is quicker and lighter. It works well for simpler issues or incremental changes.

DMAIC is often used in Six Sigma. PDCA fits better with Lean thinking. The choice depends on problem scope, time, and available data.

DMAIC also provides more statistical rigor. It emphasizes measurement and root cause validation. PDCA cycles are faster but may lack depth. For complex, high-risk issues, DMAIC offers better control.

When to Use DMAIC

DMAIC fits best when:

- A problem is clearly defined but not well understood

- Data is available or can be collected

- Root cause is unknown

- Long-term improvement is needed

It works in manufacturing, healthcare, finance, logistics, and service industries. Any process with measurable inputs and outputs can benefit.

DMAIC also fits well with digital transformation projects and data-driven decision-making. It aligns with regulatory compliance and continuous improvement mandates.

For organizations serious about change, DMAIC offers both speed and precision.

Real-World Examples of DMAIC in Action

Manufacturing: A factory reduced defect rates by 35% using DMAIC to analyze machine downtime and optimize maintenance schedules. By measuring mean time between failures, they identified patterns, changed maintenance routines, and saw dramatic results.

Healthcare: A hospital cut patient wait times by 25% by identifying bottlenecks in admissions and implementing better resource allocation. DMAIC helped map delays, track triage times, and match staffing with demand.

Finance: A bank improved loan processing time by 40% after measuring delays, analyzing approval flows, and streamlining document checks. With DMAIC, the process became transparent, faster, and more consistent.

These examples show how DMAIC turns problems into opportunities. It converts analysis into action. Every improvement came from structured thinking and data-backed decisions.

Tools Commonly Used in DMAIC

Each phase uses different tools to support decisions:

- Define: SIPOC diagrams, project charters, stakeholder analysis

- Measure: Data collection forms, process maps, Gage R&R studies

- Analyze: Root cause analysis, control charts, Pareto diagrams

- Improve: FMEA, pilot plans, process simulation

- Control: Control plans, dashboards, audits

Tools aren’t the goal. They support decisions. Knowing when and how to use them improves outcomes. Mastery comes from using the right tool at the right time with purpose.

Benefits of Using DMAIC

DMAIC provides structure without stifling innovation. It offers predictability and control while leaving room for creative problem-solving.

Advantages include:

- Fewer process defects

- Greater customer satisfaction

- Reduced operational cost

- Improved employee involvement

- Higher quality output

The process turns abstract goals into concrete steps. It removes emotion from decisions, replacing it with evidence. DMAIC also boosts team collaboration, clarifies accountability, and fosters a results-driven culture.

Final Thoughts

DMAIC remains one of the most effective methods for improving business processes. Its step-by-step structure, backed by data, creates consistent outcomes. It reduces risk, enhances quality, and delivers measurable results.

Every phase serves a purpose. Skipping steps shortens gains. Using the full method ensures sustainable success.

In a world where processes shape outcomes, DMAIC provides the map. Not just to fix problems, but to prevent them from returning.

Also Read: